How to Specify Friction Hinges

Posted On Jul 27th 2023

Posted On Jul 27th 2023

Posted On Jul 27th 2023

What is a friction hinge best used for, and how do you use it to its full potential?

When you’re specifying hinged applications in your project plans, and you’re planning on using a friction hinge for position control, it’s particularly important for the hinge’s performance, durability, and safety that you specify the correct type and torque strength of the hinge.

Common Applications for Friction Hinges |

|

Today in the Sugatsune Hardware Blog, we’re going to be looking at how to get this important detail right in your design plans by accounting for relevant factors such as torque tolerance and door moment. Let’s step into the world of friction hinges.

Most hinges deliberately minimize their friction so that the door, lid, etc., on the hinges, can swing as freely as possible along its range of motion. But a friction hinge has the opposite goal: Stop the door or lid from swinging freely (while still keeping it easy for the user to open and close it ).

Common Units of Torque |

|

| Sugatsune America friction hinges are typically rated in kgf⋅cm, with values also listed in lbf⋅in for convenience. |

Friction hinges are a part of our position and movement control hinges product group here at Sugatsune America. We’ve previously written a handy guide on friction hinges, so to learn more about what a friction hinge is, the different types of friction hinges, and how they work, check out The ABCs of Torque Hinges.

Friction hinges inherently have some variability in the exact amount of resistive torque each individual hinge generates. This is an unavoidable byproduct of the technology, and so every model of friction hinge will come with a torque tolerance rating indicating what a friction hinge is capable of actually generating torque-wise.

These tolerances are typically expressed with a plus–minus sign indicating that the true torque value can vary by the stated torque value by that percentage. For example, a torque rating of 25 lbf⋅in ±10% indicates that a given hinge’s true torque will be somewhere between 22.5 lbf⋅in and 27.5 lbf⋅in. On occasion, the tolerances are not symmetrical, and you might see (for example) a tolerance range such as 25 lbf⋅in +20% and -10%. A good manufacturing process will keep the torque tolerance ranges low, usually anywhere from ±25% all the way down to ±5%.

When you are specifying friction hinges in your design plans, you need to account for these tolerances. What a friction hinge is going to need to deliver in terms of resistive torque is something that you can control, but the individual hinges will vary in their performance beyond your control (other than replacing the hinge). You don’t want to randomly get a hinge that’s just a little bit too weak for its application, so it’s important to account for the tolerances when you choose the hinge’s level of resistive torque.

However, you also don’t want a hinge that’s much too strong for its application. If this happens, the door, lid, etc., will be hard to move and potentially even jerky, which can be an inconvenience and sometimes even dangerous.

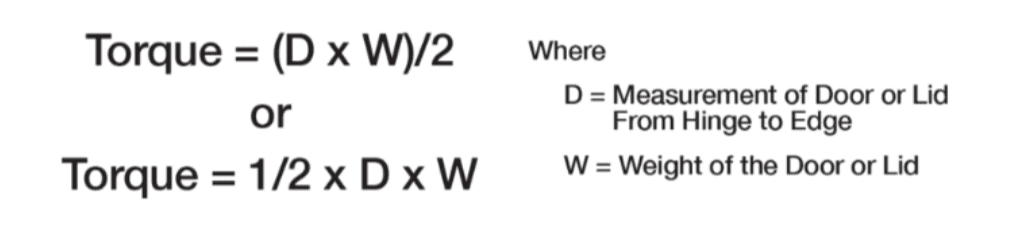

A door’s “moment” is the force of the door rotating around a hinge due to its own weight acting under the force of gravity.

Every door, lid, panel, etc., has a nonzero door moment. This force is what a friction hinge is going to need to overcome in order to reliably hold the door in place at any angle with free-stop control.

With all of that in mind, here is our rule of thumb:

For example, if you anticipate a moment of 25 lbf⋅in, then a hinge with a 30 lbf⋅in ±10% rating (minimum torque 27 lbf⋅in) will typically do nicely, as would a 35 lbf⋅in ±25% hinge (minimum torque 26.25 lbf⋅in).

It’s very important to have that buffer! After all, what is a friction hinge good for if it isn’t reliable in its free-stop position control?

Sugatsune America makes hundreds of friction hinges with various torque strengths and features, including basic position types, one-way friction hinges, dual-axis hinges (allowing for more complicated forms of motion), and specialty models such as swivel torque hinges, torque piano hinges. Visit our Friction Hinges page to see a full selection.

Some of our most popular specialty friction hinges include:

We hope this guide helps you to accurately specify friction hinges in your project. After all, what is a friction hinge good for without someone who needs it?

CAD files are available on each product’s detail page. Click the “CAD/BIM Files” tab, located in the middle of the page to download the different formats. If CAD files are not available for a specific component, please contact our Support Team

Toll Free: (800) 562-5267 (U.S.A. only)